Why choose Granken bearing steel grit

Shot blasting is the largest consumable in the shot blasting industry. The purchase amount is large and the cost is high. How to reduce the cost of shot blasting and blasting machine starts with reducing the shot blasting loss.

After many years of exploration, Granken has experimented with many customers, mastered the data, and compared them. Developed a series of bearing steel grit.

Bearing steel grit, as the name implies, uses high-quality bearing steel as raw material. Bearing steel has good wear resistance, hardness, strength, and elastic limit. Chromium can increase the stability of austenite in steel and improve the hardenability of steel. Therefore, the chemical composition of bearing steel grit and the appropriate heat treatment process can ensure that it has sufficient hardness and toughness. These excellent characteristics are unmatched by ordinary steel grit and belong to high-quality green environmental protection products.

Bearing steel contains precious metal-chromium element, which enhances its own fatigue life and wear resistance. Through continuous innovation of production technology, raw materials are not directly smelted through heat treatment process, but are directly broken through heat treatment, product particles and hardness are uniform, fatigue Long life, can save thousands of kilowatt-hours of electricity per ton, take the lead in moving towards low carbon, energy saving, and sustainable cycle development; while the traditional national standard cast steel sand does not contain precious metals such as chromium, it must be smelted, with many casting defects and high energy consumption Highly polluting products. Therefore, in the application of pre-treatment of painted parts, the bearing steel grit will not crack and break, thereby reducing abrasive wear.

The bearing steel sand metallographic structure is dense, the carbides are finely and uniformly distributed, and the surface is abraded and worn during the cleaning process. The polygonal appearance gradually rounds and becomes smaller, but the abrasive particle size of the system will always remain at a high level and the amount of dust is extremely low. At present, the national standard casting steel sand cannot keep up with heat treatment equipment and technology, uneven hardness, large brittleness, poor resistance to crushing, and serious dust pollution. As a result, the surface cleanliness of the steel after shot blasting is not high. At the same time, the bearing steel grit does not contain soluble salts. It adopts a highly automated production line, and the finished product is sealed and packaged to avoid contact with air and reduce the oxidation process. It can reduce the increase of soluble salt on the steel surface during the coating process.

Through analysis and long-term tests, the bearing steel grit not only has a long service life (at least 40% higher than the national standard steel shot) but is also an excellent product for environmental protection (small energy loss in the production process and small amount of dust generated during shot blasting) !! Let us work together to create a better environment!

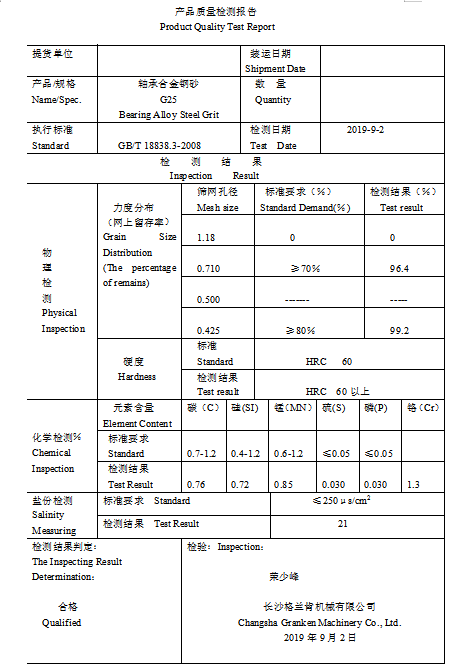

Granken also introduced advanced steel pill testing equipment at home and abroad to strictly monitor product quality. At the same time, the company samples products from time to time and tests to authoritative departments to make customers feel this visible quality assurance.

For many years, the company has always insisted on putting the interests of customers first, and solemnly promised: "If the product quality is unqualified or does not meet the contract standards, our company will return or replace it." Won the praise of customers at home and abroad.

We sincerely welcome friends from home and abroad to visit our company and negotiate!